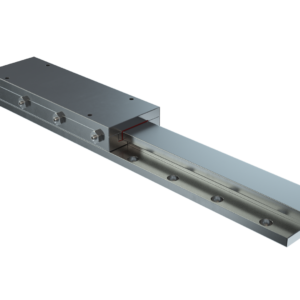

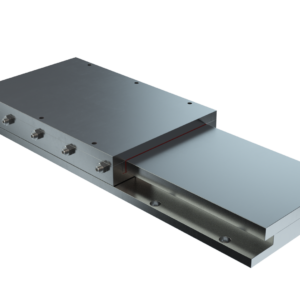

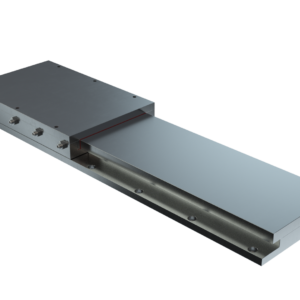

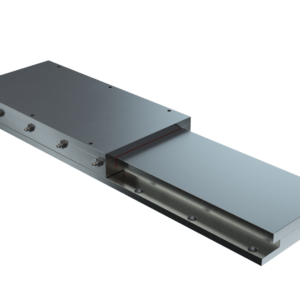

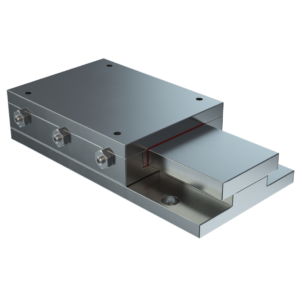

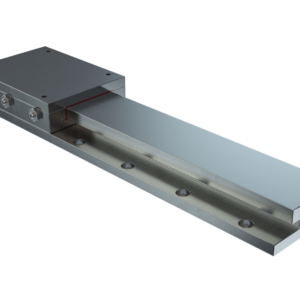

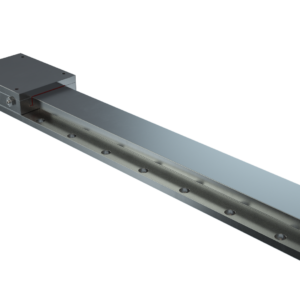

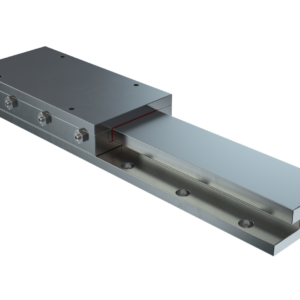

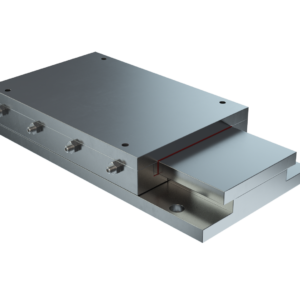

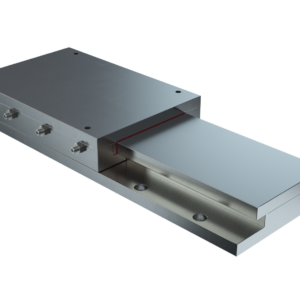

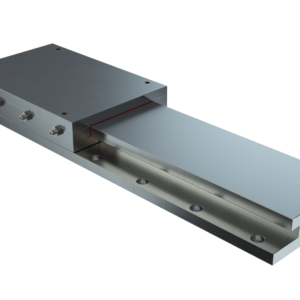

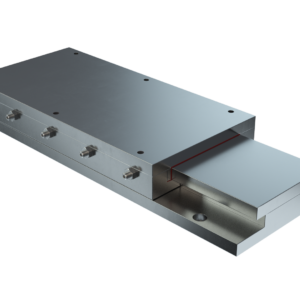

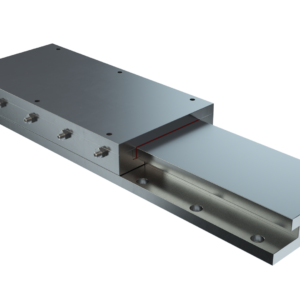

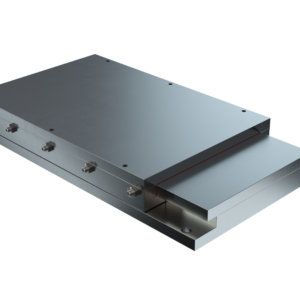

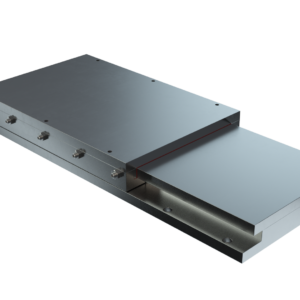

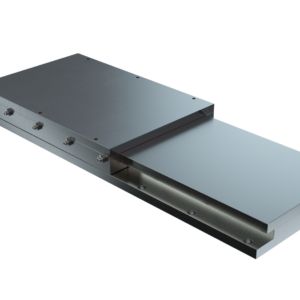

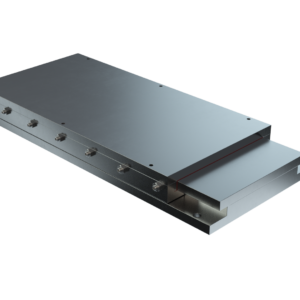

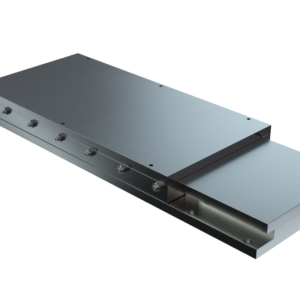

DuraBond Slide Specifications and Capabilities

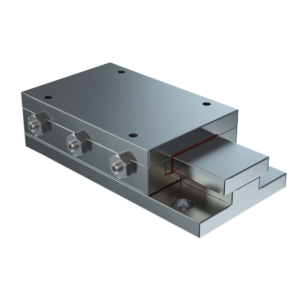

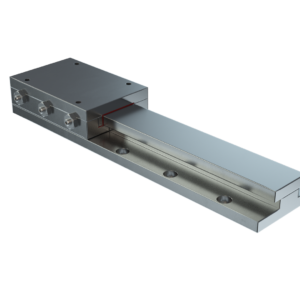

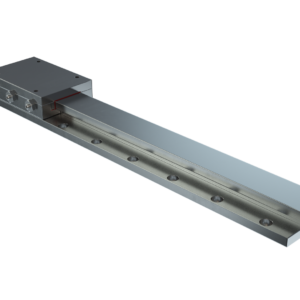

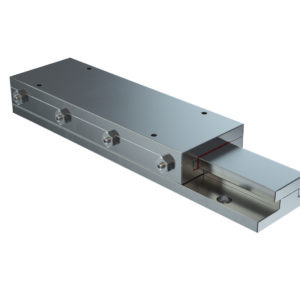

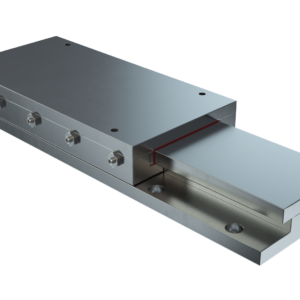

DuraBond Slide Components

- Base Stationary member of the linear slide system. Manufactured from high quality tool steel, hardened to 48-52 Rc and finish ground.

- Saddle Moving member of the linear slide system. Manufactured from high quality steel, bonded with Rulon bearing material and finish ground to create a precision slide.

- Way Saddle tracking member. Manufactured from high quality steel, bonded with Rulon bearing material and finish ground, ideal for machine use.

- Adjustment Way Saddle retaining member. Manufactured from high quality steel, bonded with Rulon bearing material and finish ground.

- Adjustment Gib Adjustable member of the linear slide system for setting clearance between the saddle and base. This member is bonded with Rulon bearing material and finish ground.

- Gib Screw High quality, fine thread Allen head screws strategically oriented along one side of the saddle for positioning the adjustment gib.

- Gib Screw Nut Locks the gib screw in place to maintain gib adjustment.

DuraBond Slide Dimensional Tolerances

- Straight line accuracy: 0.0001” per inch

- Flatness of base: 0.001″ per 12″

- Flatness of saddle top: 0.001″ per 12″

- Flatness of saddle top to base: 0.001″ per 12″

- Tracking parallelism of base and saddle: 0.0005″ per 12″

- Slide overall height tolerance: Nominal to +/- 0.005″

DuraBond Slide Load Capacity

Static Load Capacity

| Saddle Size | Horizontal Mount | Wall Mount | Ceiling Mount | Vertical Mount |

| SW02-SL03 | 750 | 188 | 258 | 700 |

| SW02-SL06 | 1,500 | 375 | 516 | 700 |

| SW03-SL04 | 1,750 | 375 | 625 | 700 |

| SW03-SL06 | 2,625 | 563 | 938 | 700 |

| SW04-SL06 | 3,750 | 563 | 938 | 1250 |

| SW04-SL08 | 5,000 | 750 | 1,250 | 1250 |

| SW06-SL09 | 9,000 | 1,125 | 2,109 | 1900 |

| SW06-SL12 | 12,000 | 1,500 | 2,813 | 1900 |

| SW09-SL14 | 24,500 | 2,625 | 4,813 | 2800 |

| SW09-SL18 | 31,500 | 3,375 | 6,750 | 2800 |

| SW12-SL18 | 45,000 | 3,375 | 6,750 | 2800 |

| SW12-SL24 | 60,000 | 4,500 | 9,000 | 2800 |

DuraBond Slide Capabilities

The technical data presented here represents typical performance values under controlled conditions. The requirements for your particular applications should be reviewed with a DuraBond Slide technical development engineer.

Recommended Operation Limits

| Temperature – Typical Range Fo | -400/+550 |

| Maximum PV (continuous) | 10,000 |

| Maximum P – PSI (static) | 1,000 |

| Maximum V – SFM (no load) | 400 |

| Slide Hardness – Minimum | Rc 35 |

| Slide Finish Recommended RMS | 8-24 |

| Slide Material | Steel |

Engineering Information

| Friction-Static & Dynamic | .15-.25 |

| Water Absorption ASTM D570 | 0% |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | Inert |

| Thermal Conductivity BTU/hr/sq. ft./ F/in. | 2.3 |

| Linear Coefficient of 780F – 2000F | BD 3.5×10-5 BL 6.2×10-5 |

| Thermal Expansion 780F – 3000F | BD 3.6×10-5 BL 7.0×10-5 |

For more information on DuraBond Slide’s capabilities and performance criteria, such as bearing pressure, bearing speed, wear rate and friction, please download our full Performance Criteria document here.

Shop Online

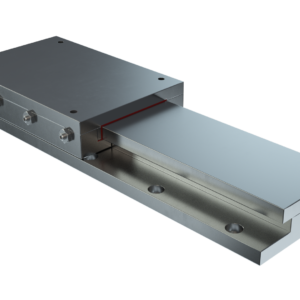

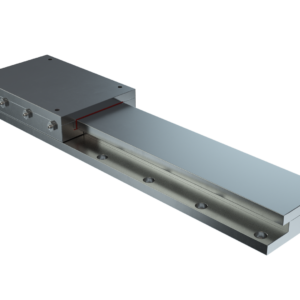

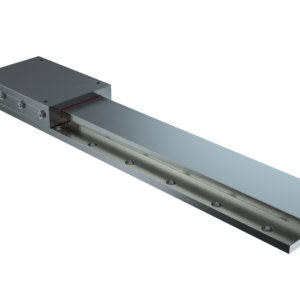

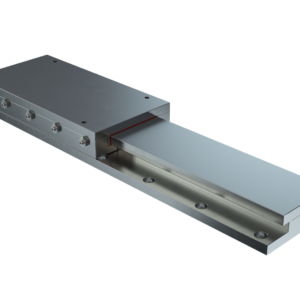

2" Width Slides

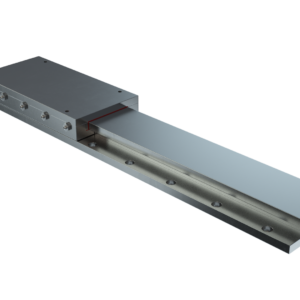

4" Width Slides

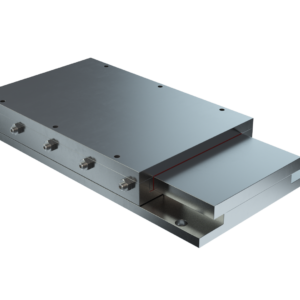

9" Width Slides

3" Width Slides

6" Width Slides

12" Width Slides

Contact DuraBond

If you have comments or questions or would like to request a custom linear slide quote, please contact us through the form.

5627 Airline Highway

Fruitport, MI 49415

1-800-933-0404